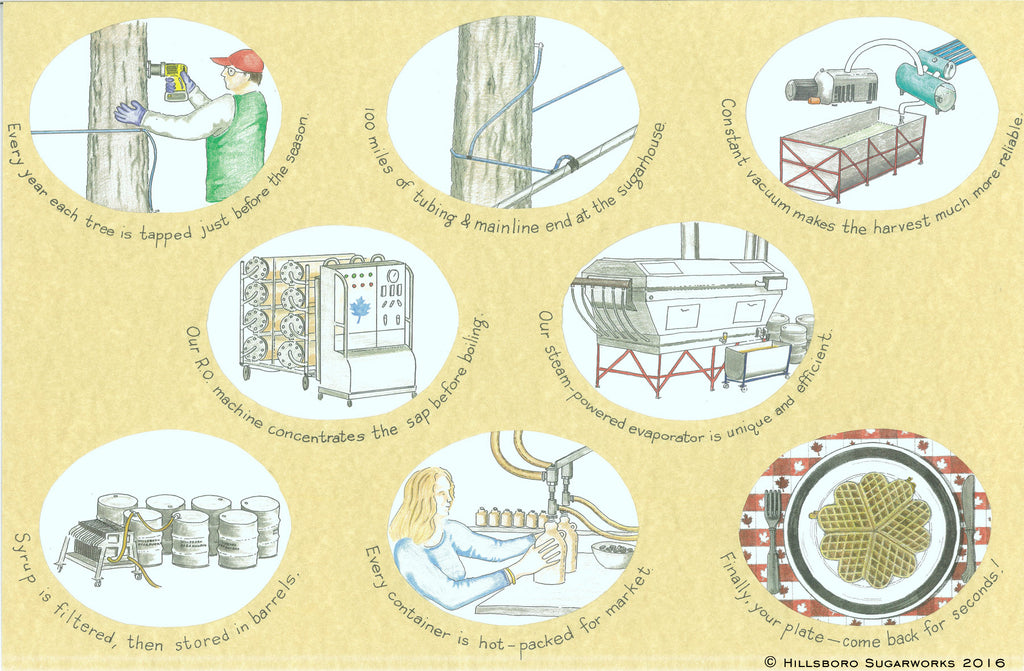

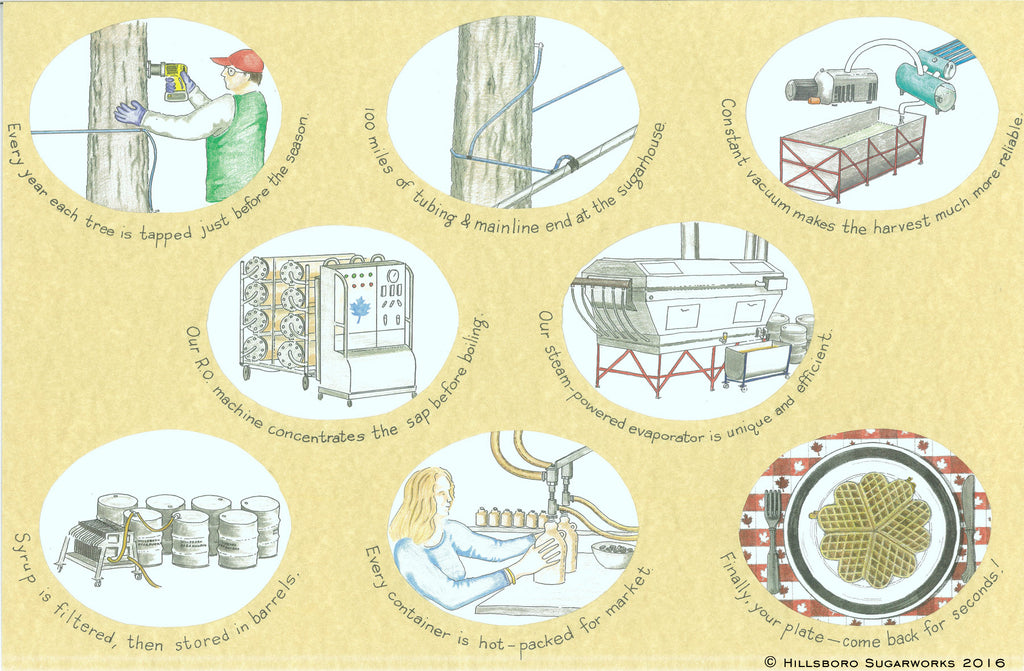

Tapping the trees

Starting in early February, and drifted snow and freezing cold temperatures, we drill fresh tap holes in each tree. We commute into the woods on snowmobiles. Tapping 15,000 holes in our maple trees, and snowshoeing the 75 miles of tubing takes between two and three weeks under the best conditions. When the snow is deep we can take at least another week, but it is essential that the holes are drilled when winter breaks, so it is crucial to start early enough to get everything done even if the conditions are tough.

Starting in early February, and drifted snow and freezing cold temperatures, we drill fresh tap holes in each tree. We commute into the woods on snowmobiles. Tapping 15,000 holes in our maple trees, and snowshoeing the 75 miles of tubing takes between two and three weeks under the best conditions. When the snow is deep we can take at least another week, but it is essential that the holes are drilled when winter breaks, so it is crucial to start early enough to get everything done even if the conditions are tough.

100 miles of tubing and mainline

Our sugarbush covers about 200 acres on the steep hillside above our sugarhouse. It is crisscrossed with about 100 miles of plastic tubing and pipes combined, that all flow downhill to the sugarhouse. It looks like a blue spider web. The entire network must be graded downhill and remain intact. Walking the entire system on bare ground takes quite a few days. On snowshoes, it can take much longer. Between storms and critters, such as bears, woodpeckers, chipmunks, porcupines and moose, we stay pretty busy maintaining the tubing system.

Our sugarbush covers about 200 acres on the steep hillside above our sugarhouse. It is crisscrossed with about 100 miles of plastic tubing and pipes combined, that all flow downhill to the sugarhouse. It looks like a blue spider web. The entire network must be graded downhill and remain intact. Walking the entire system on bare ground takes quite a few days. On snowshoes, it can take much longer. Between storms and critters, such as bears, woodpeckers, chipmunks, porcupines and moose, we stay pretty busy maintaining the tubing system.

Constant vacuum

The 100 miles of tubing is under constant vacuum during the season. Vacuum helps assure a good crop even with bad sugaring weather. Once the maple trees are tapped, there are two jobs----boiling sap and finding leaks. Looking for leaks makes you very aware of how many critters are in the woods. The more leaks you find--- the more sap you boil.

The 100 miles of tubing is under constant vacuum during the season. Vacuum helps assure a good crop even with bad sugaring weather. Once the maple trees are tapped, there are two jobs----boiling sap and finding leaks. Looking for leaks makes you very aware of how many critters are in the woods. The more leaks you find--- the more sap you boil.

Reverse osmosis

Our reverse osmosis machine concentrates the sap before boiling. This machine, which uses the same technology as a desalination machine, reduces our energy usage by about 90%. This is an example where technology is completely beneficial to the environment.

Our steam powered evaporator

We boil our sap on a relatively uncommon evaporator. Almost all maple evaporators have some sort of a flame directly heating a metal pan that contains maple sap. On the bottom of the pan is a flame--- on top, sap. The flame can be produced from burning wood or oil. This method has been used for over 100 years with few changes.

Our evaporator uses an entirely different approach. It is homemade and home designed using commercial components. We boil our sap using a steam powered evaporator. Our sap is heated and boiled away with stainless steel pipes that are submerged in the pan. These pipes contain 300° steam. The sap on the outside of the pipes boils intensely. Our system is completely controllable and highly efficient.

Our evaporator uses an entirely different approach. It is homemade and home designed using commercial components. We boil our sap using a steam powered evaporator. Our sap is heated and boiled away with stainless steel pipes that are submerged in the pan. These pipes contain 300° steam. The sap on the outside of the pipes boils intensely. Our system is completely controllable and highly efficient.

The steam within the system is recirculated over and over, and the temperature coming out of our smokestack is exceptionally cool compared to a conventional evaporator. Our energy efficiency, quality control and speed are greatly enhanced by using this form of evaporator.

Filtration and pasteurization

Since maple syrup is a concentrated sugar solution it boils at a higher temperature than water. Depending upon the weather conditions, syrup boils somewhere just above or below 219°. Because of this, it comes off the evaporator naturally pasteurized. Once we are confident that it is the exact right density, it is drawn off from the evaporator, filtered to remove impurities and stored in 40 gallon stainless steel barrels. Once it's in these barrels the flavor and density remain very stable.

Since maple syrup is a concentrated sugar solution it boils at a higher temperature than water. Depending upon the weather conditions, syrup boils somewhere just above or below 219°. Because of this, it comes off the evaporator naturally pasteurized. Once we are confident that it is the exact right density, it is drawn off from the evaporator, filtered to remove impurities and stored in 40 gallon stainless steel barrels. Once it's in these barrels the flavor and density remain very stable.

Packing syrup

Every week in preparation for filling our maple syrup orders to bring to market, we package our syrup into individual containers. The syrup is reheated to 180° to assure that it is hot-packed before filling the container. Within a week or two these containers are on a store shelf or have filled an Internet order. Maybe it’s on your table?

The 100 miles of tubing is under constant vacuum during the season. Vacuum helps assure a good crop even with bad sugaring weather. Once the maple trees are tapped, there are two jobs----boiling sap and finding leaks. Looking for leaks makes you very aware of how many critters are in the woods. The more leaks you find--- the more sap you boil.

The 100 miles of tubing is under constant vacuum during the season. Vacuum helps assure a good crop even with bad sugaring weather. Once the maple trees are tapped, there are two jobs----boiling sap and finding leaks. Looking for leaks makes you very aware of how many critters are in the woods. The more leaks you find--- the more sap you boil.